A solar PV module is a collection of solar cells, mainly connected in series.These combinations of solar cells provide higher power than a single solar cell.The PV modules are available in the power range from 3 watt to 760 watt.They really form the basic building block of PV systems as power generating unit.With the further connection of PV modules together, one can generate a very large amount of power, in the range of megawatts or MW.

The output of a PV module depends on ambient conditions, temperature, and solar radiation intensity. A single solar cell can generate a very less amount of power depending on the area of the cell. A single solar cell would generate power in the range of a fraction of a watt (like 0.1 to 7 Watts)

But in practice, the power requirement by our loads like fans, TV, and refrigerators is in the range of several 100s of watts and sometimes more than 1000 watts or kilowatt kW.

When we talk about grid electricity and conventional power plants we talk about power in the range of millions of watts or MW. Therefore, a single solar cell is of no use for running the actual loads in-home or supplying power to the electricity grid.

We must generate solar PV power in large amounts in several watts, kW, and MW. In order to fulfill the high-power requirements

The number of cells are connected together to make a solar PV module. In this way, the solar PV module is a device that can supply larger power, larger than what individual solar cell can supply.

A single solar cell is shown in the picture in front of you. It is shown to have a typical shape of crystalline silicon solar cells, having lines across it which represent the metal line of top contact.

The cell is shown to have two terminals, a positive terminal and a negative terminal.When light falls on solar cells, the voltage gets generated across these two terminals.

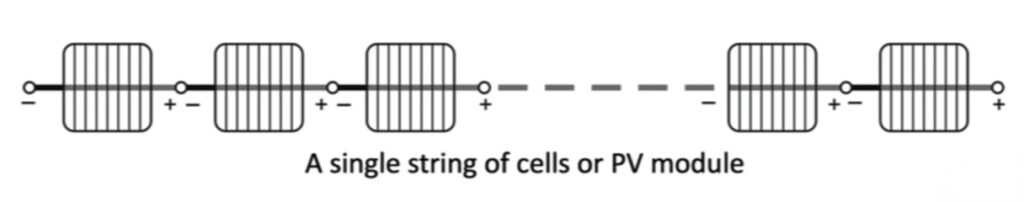

In PV modules, many cells are connected together. The cells are connected in series, wherein the positive terminal of one cell is connected to the negative terminal of the next cell and this is repeated to make a string of solar cells, or a solar PV module.

A solar PV module is a device in which several solar cells are connected together to generate more power than a single solar cell.

When we connect cells in series, we get a string of solar cells. The string of solar cells will also have two terminals.

When we connect cells in series the voltage of solar cells gets added, therefore, the terminal voltage of a PV string (PV module) will be higher and equal to the sum of all the solar cells connected in series.

Example, the terminal voltage of a solar cell will be 0.5 V under operating conditions if 6 cells are connected in series the terminal voltage 0.5 × 6 = 3 V.

If a 36 solar cells are connected in series, then terminal voltage of series of 36 cells, or PV string of 36 cells will be 0.5 x 36 = 18 V.

Rating of PV Module

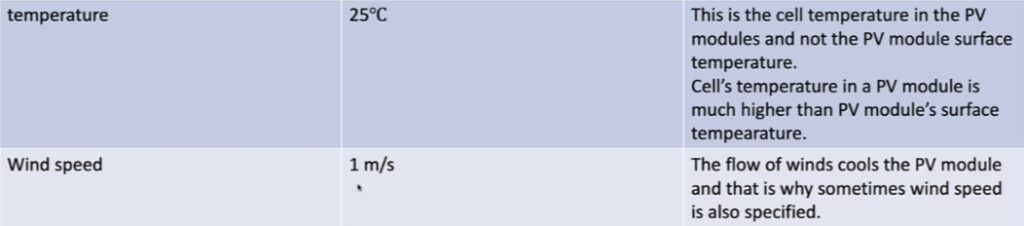

The parameters of the solar PV modules (Voc, Isc, W) mentioned by the manufacturer are measured under some standard conditions of temperature 25°C and solar radiation 1000 W/m².

These test conditions are known as standard test conditions STC.

The most important parameter of a PV module is its peak output power. The solar PV modules are rated in terms of their peak power W output. It is the most important parameter from a user’s point of view.

The Wp is specified by the manufacturer under so-called standard test conditions STC. The module rating under STC is widely accepted by manufacturers and by users.

Departure from STC

The conditions specified in the STC do not occur most of the time and in locations.

This happens mainly because of two reasons; the real solar irradiation is normally less than 1000 W/m² and the module temperature under real operation is more than the STC-specified temperature of 25 °C.

Both of these reasons result in lower module power output than expected under the STC condition.

Standard PV Module Parameters

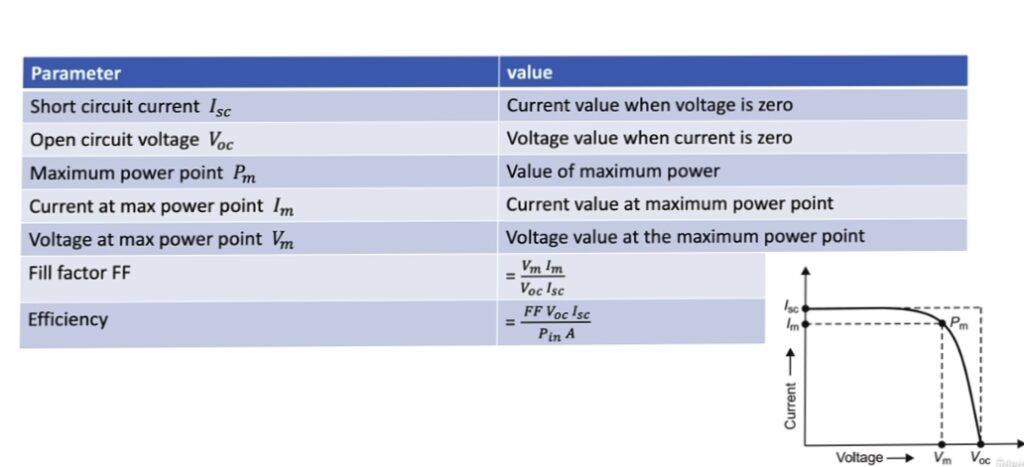

Short circuit current Isc:

It is the maximum current a solar PV module can produce. It happens when two terminals of a PV module are shorted, hence the name short circuit current. For a given solar cell area used in module, the higher the Isc the better is the PV module. It is measured in ampere. The value of this maximum current depends on PV module technology, PV module area, the amount of solar radiation falling on PV module, angle of PV module with respect to the sun’s rays etc.

Many times people are given current density rather than current. The current density is obtained by dividing the Isc by the area of solar PV module. The current density is normally referred by symbol J, therefore, the short circuit current density Jsc = Isc/A

Open circuit voltage Voc:

It is the maximum voltage that solar PV modules produce. It happens when two terminals of the PV module are left open.

For a given number of cells in series in a PV module, the higher the Voc better is the PV module. The value of this maximum open circuit voltage mainly depends on PV module technology and operating temperature.

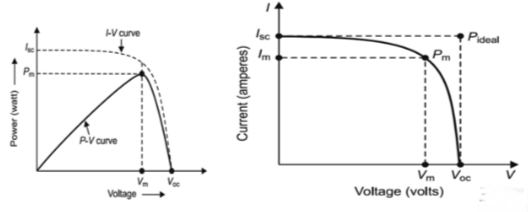

Maximum power point Pm:

It is the maximum power that a solar PV module produces under STC. For a given PV module dimensions, the higher the Pm the better the PV module.

It is given in terms of watts (W). Since it is maximum power or peak power it is sometimes also referred to as Wpeak.

A solar PV module can operate at many current and voltage combinations. But a solar PV module will produce maximum power only when operating at a certain current and voltage

At small voltage and current, the power output of a PV module is small. As the voltage increases, the power output increases and reaches a peak value corresponding to Im and Vm of a PV module. This maximum power point is denoted as Pm . If a PV module operates at a voltage higher than Vm the module output power decreases again and at open circuit voltage V oc

PV module power decreases to zero. Pm = Vm*Im

Note: Pm is the maximum power output under standard test condition. The maximum PV module power output Pm is obtained only when solar Pv module operates at certain current Im and voltage Vm in STC solar radiation condition of 1000 W/m². If PV module operates at any other combination of current and voltage under STC, we will not get the maximum possible output power from the PV module.

Current at the maximum power point Im:

This is the current which solar cell will produce when operating at maximum power point.

Voltage at maximum power point Vm:

This is the voltage which solar cell will produce when operating at maximum power point. The Vm will always be lower than Voc.

Fill factor (FF):

FF is the ratio of the area covered by Im Vm rectangle with the area covered by Isc – Voc rectangle. It indicates the square-ness of I-V curve. The higher the FF, the better the cell. The FF of a cell is given in terms of percentage (%). Cell with squre I-V curve is a better cell.

FF = Vm Im / Voc Isc =Pm / Voc Isc

Efficiency η :

The efficiency of a solar cell is defined as the maximum output power Pmax divided by the input power Power in. The efficiency of a cell is given in terms of percentage (%), which means that this percentage of radiation input power is converted into electrical power. Power in for STC is considered as 1000 W/m². This input power is power density (power divided by area), therefore, in order to calculate the efficiency using Pin at STC, we must multiply by solar cell area.

These parameters can be best understood by the current-voltage curve (I-V curve) of the solar cell.

Total numbers of cell in PV Module

The module manufacturing technology was developed in the 1980s. At that time, the Pv modules were designed for charging batteries of 12 V terminal voltages.

therefore, one of the module’s requirements is to provide the sufficient voltage to be able to charge 12 V batteries under typical daily solar radiation.

Now, voltage source will be able to charge battery if the source voltage is higher than the battery voltage. It means that the module voltage, under daily radiations should be higher than the battery voltage.

Generally, it is expected that the PV module must provide about 15 volts or around this value in all operating conditions, meaning low solar radiation like in morning and evening, and high temperature like in summer.

PV module design for 12 V battery level has now become standard. For large power modules, the design is done for 24 V battery level two batteries in series, 36 V battery level three batteries in series, etc. Or, we can say the Pv modules are designed to provide voltage in a multiple of 12 V battery level, that is 12V, 24V, 36V, 48V etc

We must note here that for the 12 V battery voltage level, PV module Vm should be around 15 V, and for the 24 V battery voltage level, PV module voltage should be around 30 V. similarly, for the 36 V battery voltage level, PV module voltage should be around 45 V.

Also, note here that when we refer to the module voltage level, we refer to the module voltage at the maximum power point.

For instance, the charge controller, MPPT, and inverter are designed in such a way that they can take input voltage in multiples of 12 V. Since a single solar cell provides a smaller voltage, it is required to connect many solar cells in series to get a higher PV module voltage to charge a battery.

There are different technologies for solar PV cells. Depending upon each technology, the number of cells to be connected in series is decided. The decision of how many cells to connect in series in a PV module is determined by the Voc of the cell.

For crystalline silicon solar cell technology, the required voltage for charging a 12 V battery can be obtained by the series connection of 36 solar cells.

Why 36 cells in series?

Commercial Si solar cells generally have a Vm of about 0.5 Volts at 25°C. We also know that due to the higher operating temperature being higher than specified by STC, 25°C, the voltage Vm and Voc decrease.

The solar cell under encapsulation operates at higher temperature resulting in loss of voltage by about 0.08 V.

Vm=Vm (STC)-loss of voltage due to higher temperature Vm = 0.5-0.08 = 0.42 V

Now, we want about 15-volt module output voltage in all conditions, and each solar cell will give us about 0.42 V.

Now, in order to calculate the number of cells to be connected in series, the required voltage must be divided by the possible operating voltage from one cell.

15 The Number of cells in series = 15/0.42=35.7 approximately 36 cells.

Estimation of the number of cells in a module depends on the Vm and loss of voltage due to temperature, both of these depend on the cell technology.

Thus, with the technology, the number of cells to be connected in series to get desired voltage can change.

If Vm (STC) is higher, we need less number of solar cells in series and if Vm (STC) is lower, we need more number of solar cells in series to get desired operating voltage.

Nowadays, solar PV modules are also available to charge 8 V and 12 V batteries. Since the battery terminal voltage is lower the module voltage requirement will also be lower and the number of cells one must connect in series will also be lower.

Procedure to Design Number of Cells in a Module

Step 1: find out the Vm at STC of a solar cell given technology

Step 2: find out the loss of voltage (loss of Vm)

Step 3: available voltage at operating conditions = Vm (STC) – loss of voltage

Step 4: note down the required PV module voltage

Step 5: divide the required module voltage by available operating volatge to get the number of cells connected in series

The Number of cells in series = Required PV module voltage / Vm(STC)-loss of voltage

Designing Wattage of a PV Module

The wattage of the PV module is one of the most important parameters from the user’s perspective.

When a user buys a PV module from a market, the cost of the PV module is given in terms of the wattage that a PV module can generate.

Normally, the PV module output power changes with the solar radiation intensity, which changes throughout the day, therefore, all manufacturers rate the PV module power output under one certain condition, which is known as standard test condition STC.

The STC is corresponding to 1000 W/m² of solar radiation at 25 °C of cell temperature.

Under this condition, if the PV module is operating at maximum power point, the output power of the module is known as peak power and written as Wpeak

Normally, the solar radiation intensity is lower than 1000 W/m² and cell temperature under operation is higher than 25°C; both of these effects decrease the power output of module.

Thus, in almost all operating condition, the actual output power of PV module is less than the rated peak power or W, of PV module given by manufacturer.

The output power of a PV module depends on the voltage and current at which the module is operating.

If the module operates at current Im and voltage Vm then the power generated Pm by the PV module is maximum.

The current generated by a solar cell depends on area of the cell.

Smaller area solar cell produce small current and large area solar cell produces large current.

A parameter called current density, which is current divided by area is independent of the cell area.

The typical current density of solar cells of different technology is given. For instance, for crystalline silicon solar cell technology, the current densities of commercial cells are in the range of 30 to 35 mA/cm² given under STC, and the size of solar cell can vary from 5 cm² cells to large 225 cm² cells.

Thus, knowing cell area and current density of cell of given technology, we can estimate the current that a cell produces under STC, that is Jsc × A, and this current will be nothing but Isc.

In the module, since cells are connected in series, normally, in the module designed for 12-volt operation, the current produced by a single solar cell is the current of the PV module.

Thus, if a large area cell is producing 5 A Isc, if there are 36 identical cells connected in series, the Isc of the PV module will also be 5 A.

The wattage of a PV module depends on the current and voltage of a PV module at peak power condition.

Total current produced by a solar cell is obtained by multiplying the current density by the cell with its area.

Factors affecting electricity generated by a solar PV module:

In practical applications, the PV module output varies with variations in ambient conditions like temperature, solar radiation, angle of sun rays, etc.

The change in PV module parameter output power with a change in ambient condition is important to understand. This will be useful in estimating the possible generation of electricity using solar PV modules and the possible performance of PV systems in a given condition.

There are five common factors affecting the power generated by solar modules.

- The conversion efficiency

- The amount of light

- The operating temperature

- The solar cell area

- The angle at which daylight falls

Effect of conversion efficiency η

The modules consist of several cells electrically interconnected to each other in series or and parallel. A solar cell converts some fraction of light energy falling on it into electrical energy. In this way, a PV module also converts only some portion of the total light falling on it into electrical energy.

The ratio of electrical energy generated to the input light energy is referred to as the conversion efficiency of PV modules. The efficiency of modules is always less than the efficiency of solar cell used in it.

All solar cells used in PV modules may not be perfectly identical, that is, all the parameters of solar cells may not be exactly identical. The difference in solar cells used in PV modules results in less power generation when connected in modules as compared to the case when all cells work individually. Also, the module area is always larger than the total cells area as the spacing area between the cells is considered. The area considered for the calculation of efficiency affects the conversion efficiency.

The conversion efficiency of module basically depends on the solar cells used and the method used for interconnecting them. In a module, the cells can be inter-connected in series or parallel combinations.

Once a module is assembled, its efficiency value becomes fixed, and it generally does not change. The efficiency of a module is given in terms of the maximum power or peak power that the module can generate for a given input of solar radiation.

The maximum power output of the module depends on the voltage developed across the module terminal and the current it can supply. In a module, the type of cells inter-connection greatly affects the output power.

η = Pm/ Pin A

Pm = η Pin A

For given input power, the value of the output power is directly determined by the value of module’s conversion efficiency and module area.

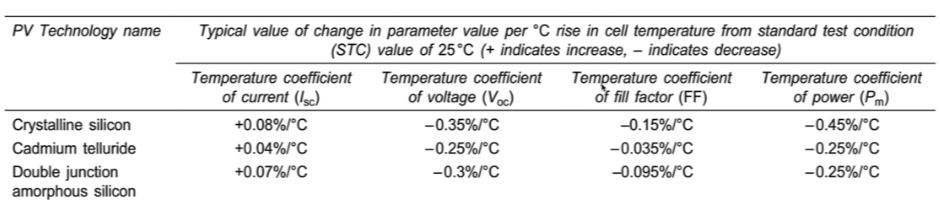

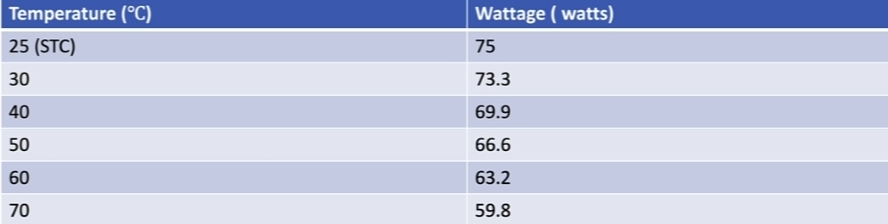

Effect of change in PV module temperature

The solar PV modules output voltage, power, and efficiency ratings are given at STC = 1000 W/m² and 25°C.

The PV module output voltage, PV module efficiency, and output power depend on the cell temperature in the PV module.

In practical applications, the operating temperature of solar cells in PV modules may be different than 25°C. Moreover, in practice, the cells in a PV module are encapsulated with a glass cover. The presence of glass cover has greenhouse effect, which result in the heating of solar cells and increase in their temperature.

The change in temperature from standard operating temperature directly affects the output voltage of a PV module.

With increase in cell temperature in PV modules, the voltage output of PV module decreases, which results in decrease in PV module efficiency and PV module output power.

the short circuit current of PV module increases with increase in cell temperature, while other parameters like open circuit voltage, efficiency and output power decreases with increase in cell temperature in PV modules.

Normally, the Wp rating of the PV module is one of the most important parameters.

In a real-life situation due to a higher cell operating temperature than STC temperature, the actual maximum output power of modules is lower than the STC value. Using the temperature coefficient of the module parameter, the change in value of parameter with increase in temperature can be estimated.

In this way, if we know the temperature coefficient of power, we can calculate how much will be drop in peak power output of a PV module in real-life operating condition.

Ptemp = PSTC-(TC PSTC ∆T)

Using the above formulae, one can find the change in any parameter value for a given cell operating temperature.

The above formula can be written for any parameter.

For instance, the formulae for change in maximum module voltage due

to increase in the cell temperature in PV module will be:

Vm.,temp = Vm,STC – (TC Vm,STC ∆T)

PV module area

Generally, the modules of a large area give high power compared to the modules of a small area. It is very important to understand the reason behind it.

When we say area of a module has increased or decreased, it means the area of module increases or decreases with the increase or decrease in the number of cells in a module.

For example, in a module there are 36 cells and the area of each cell is 156 cm² then total area of 36 cells = 36 × 156 = 562 сm² = 0.562 m²

Now, if the number of cells in same module is increased to say 72 cells then the total area of cells becomes 1.12 m² double of 0.562 m².

You learnt that the maximum output power of a module depends on the maximum output current and the maximum output voltage.

For example, if at STC module of area 1.475 m² having Vm = 26 V and Im 6.73 A Pm 175 W then a module 2.95 m² having Vm = 52 V and Im = 6.73 A will give Pm = 350 W under same input sunlight intensity.

From above example. The question arises; why has the output voltage and output power doubled with the increase in module area?

This is because Vm and Im of modules depends on the series or parallel types of cells inter-connectivity used. When strings of cells are connected in series, the voltage is additive and current is fixed.

When the strongs of cells are connected in parallel, the current is additive and voltage is fixed.

So, when the strings of cells in a module are inter-connected in series, high output voltage is obtained. When the strings of cells in a module are inter-connected in parallel, high output current is obtained.

Large module area means high power and small module area means low power.

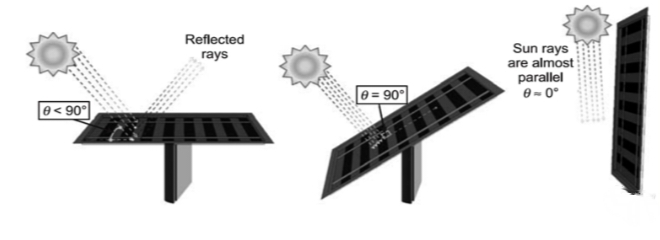

Angle of light falling on PV module

The angle of sunlight with respect to module greatly affects the output power.

The modules produce maximum power when sunlight falls perpendicular to the surface of a module.

When the light does not fall perpendicular on the module, it always gives less output power than maximum possible output power.

This is because when light falls at some angle, some part of light falling on module is reflected.

Hence, the actual light utilized by a module is less than the amount of light falling on it.

So, the output power generated is less when light is not falling perpendicular to the module.

Therefore, one should always try to install a module in such a way the most of the time sunlight is close to perpendicular, specially in the afternoon time when the intensity of sunlight is high.

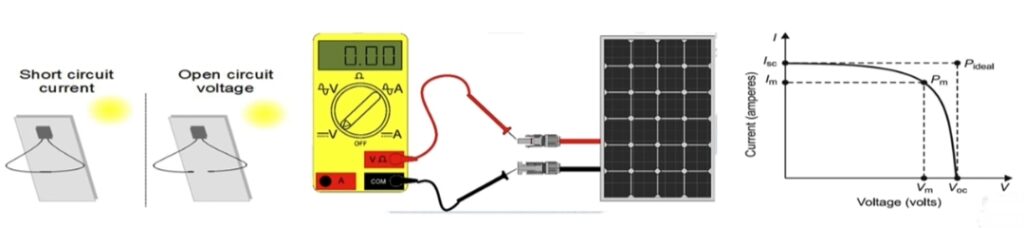

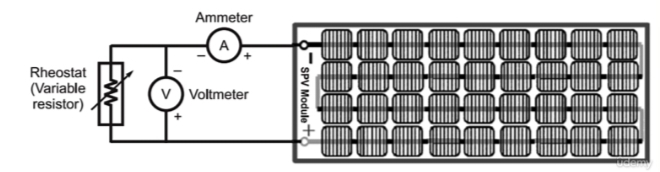

Measuring module parameters

The parameters can be measured by means of the measuring devices like open circuit and maximum voltage, short circuit and maximum current and parameters which can be calculated using measured parameters are fill factor, maximum power point and efficiency.

For measuring the module parameters, the following equipments are required:

- Ammeter or multimeter

- Voltmeter or multimeter

- Rheostat

- Connecting wires

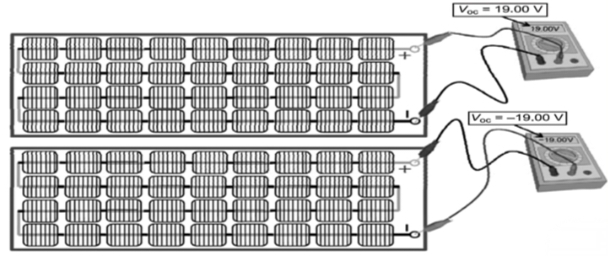

Measuring open current voltage

When you are measuring Voc or open circuit voltage of a module, there should not be any load connected to the module, and it should be in open circuit condition.

For measuring Voc, first set the multimeter knob to voltage measurement and set the range of voltage according to the given module (normally 6 V, 12 V, 24 V, etc).

Then connect the two terminals of multimeter/voltmeter across two terminals of SPV module directly. Ensure that the terminals of same polarity of multimeter and module are connected together.

In this arrangement, the reading shown by the multimeter/voltmeter is open circuit voltage of the given SPV module.

If a negative sign is shown in the meter with reading, it indicates that the appropriate polarity of the module terminal and meter terminal is not connected. Reverse the connection and then measure again.

Measuring Short circuit current

When you are measuring Isc or short circuit current of a module, there should not be any load connected to the module, it should be in short circuit condition.

For measuring Isc using a multimeter, first put the probes of the multimeter into the current measurement slots given in multimeter, and then set multimeter knob to appropriate current range according to the modle rating.

The typical Isc values of modules could be in range starting from 0.1 A to 10 A.

Then connect the opposite polarity terminal of multimeter/ ammeter and SPV module directly.

The reading shown by multimeter/ammeter in this case is short circuit current of the given SPV module.

If a negative sign is shown in the meter with some reading, it indicates that the appropriate polarity of the module terminal and meter terminal is not connected.

Measuring maximum current

This is a very useful measurement for any SPV module to measure its performance in the laboratory as well as on the field in real-time. The measurement would require two multimeters or a voltmeter and an ammeter and a rheostat.

For measuring the I-V curve, the solar PV module has to be connected in series with the rheostat, negative terminal of a SPV module to the one end of the rheostat and other end of rheostat should be connected to the positive terminal of the multimeter/Ammeter.

The voltmeter or multimeter for voltage measurement is directly connected across the SPV module.

If by mistake, the connection of positive and negative terminals of voltmeter and ammeter is not done properly, it is not a problem, the difference however would be that the meters will show readings with negative sign.

If the signs of reading are negative, make changes in connections.

After making the connections, now you are ready to make the measurements.

Make the table with three columns one for serial number, one for noting down the voltage and one column for noting down the current. One extra column should be empty to make calculations for power ( IxV).

After doing all the connections, in order to start the measurement, slide the rheostat at one side where the voltage should be maximum and current should be minimum, and note down the values of current and voltage at that instant, and note the readings in table.

Now slightly slide the rheostat, and readings of current and voltage will change. Note down the readings again.

Higher wattage modules

The crystalline Si cell technology is the most commonly used technology. For this technology, the large area solar cells are available in either size 12.5×12.5 cm² or 15×15 сm².

These size of solar cells are commonly used, particularly, in all modules which are used in grid-connected PV plants.

Crystalline silicon cells with larger than this are available.

How much peak power these modules can provide? What to do if we want more power output per module?

We now know that the PV modules are typically designed to produce about 15 V Vm under operating conditions and in order to get this voltage, there are about 32 to 36 cells connected in series depending on Vm of individual cells and operating temperature. The current produced by the cells depends on the area and current density. The current density of commercially available crystalline Si solar cell is about 30 mA/cm².

Let us take 35 mA/cm²here for estimation, relatively towards bit higher side. Thus, the maximum possible short circuit current that we can get from modules with large area solar cells is:

Isc = Jsc A

Isc = 35 x 12.5×12.5 = 5.46 A

Isc = 35 x 15×15 = 7.87 A

We know that Im is normally about 90 to 95% of the Isc. Let us assume 90% here for calculations.

Therefore,

Im = 0.9 Isc ,

Im = 0.9x 5.46 = 4.91 A (for 12.5×12.5 cm² cells)

Im = 0.9x 7.87 = 7.08 A (for 15×15 cm² cells)

Now, the maximum wattage that we can get using these two types of cells are:

Wp = Vm Im

Wp = 15 x 4.91 = 73.65 watt

Wp = 15 x 7.08 = 106.2 watt

Using the best available crystalline Si cell technology with large-area solar cells, the maximum possible wattages possible are 73.65 watts and 106.2 watts the modules designed can be used for 12 volts system voltages.

In order to get higher voltages, two or more modules are connected in series.

In order to get more current, two or more modules are connected in parallel.

In this way, by making series and parallel connections, the voltage and current of a PV system as well as the power of a PV system can be increased.

We can increase the power output of crystalline silicon PV modules more than what we have just calculated.

A single solar cell provides Vm of about 0.5 V, and the modules of 15 V are obtained by connecting many individual cells in series.

Higher voltage modules higher than 15 V can be designed by connecting a large number of cells in series.

In this case, larger than 30 to 36 cells are normally connected in the case of crystalline silicon cell technology.

thus, by connecting more cells in series we can get higher voltage, and thus, higher power from the module.

In similar way, if we connect more cells or strings of parallel, we can get more current and in this way, more power from the modules.

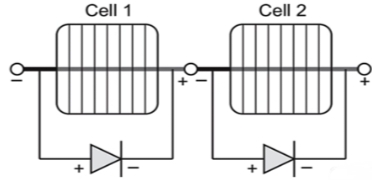

Bypass diode

In solar PV modules, in almost all cases, all the solar cells, identical in nature, are connected in series.

When light falls on a PV module, the same current is generated in all solar cells which flow through the PV module.

now, due to some reason, if one of the solar cells gets shaded no light falls on one cell then the current generated by that cell will be lower than the rest of the solar cells.

Since the cells are connected in series, the shaded solar cell generating low, or no current will resist the current flow generated by non-shaded solar cells generating full current.

In this case, the shaded solar cell becomes a load for the other cells, and the power generated by other solar cells may get dissipated in the shaded solar cells.

Due to this, the shaded solar cell can become very hot, forming hot spots in the PV module.

The hot spots sometimes can give rise to the breaking of the glass cover in the PV module or in the worst case, can cause a fire.

Therefore, local heating of solar cells in a PV module due to shading should be avoided.

A bypass diode is used to avoid the destructive effect of hot spots or local heating in series connected cells in PV modules.

A diode, called a bypass diode, is connected in parallel with solar cells with opposite polarity to that of a solar cell.

In normal conditions with no shading, the bypass diode is operated in reverse bias condition, effectively in an open circuit.

But if a series connected cell is shaded, reverse bias will appear across it. This reverse bias will act as a forward bias voltage for the bypass diode since it is connected with opposite polarity.

In this way, the bypass diode will carry the current, rather than shaded cell meaning bypassing the current from shaded cell.

By bypassing the current, the solar cell gets protected by heating and causing permanent damage to the PV module.

Ideally, there should be each diode for each solar cell in the PV module but practically due to cost reason, there are few bypass diodes which are connected in PV module.

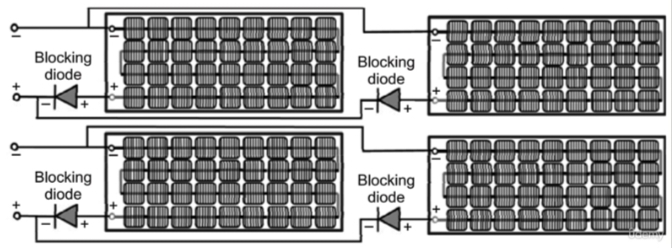

Blocking diode

In standalone PV systems, PV modules are used to either supply the load during the daytime or to charge a battery. In the daytime, energy is generated by the PV module and supplied to the battery. When there is no sunlight, like at night, the SPV modules stop producing energy and become idle. During the night, charged batteries supply energy to the SPV modules. This is a loss of energy and should be avoided.

In order to avoid the flow of current from the battery to solar PV modules, a diode called a blocking diode is used to block the current flow.

Thus, the blocking diode prevents the discharge of the battery into the SPV module.

Diode ratings

The diodes used for bypass and blocking are different for the different modules/cells depending on their current and voltage ratings.

There are various ratings of diodes available. The rating of a bypass diode, which is used for 16-19 cells in series, is the total current flowing through the series of connected cells in a string.

That means, one module of 36 cells contains 2 bypass diodes and a module with 72 cells contains 4 bypass diodes.

Typically, the rating of the bypass diode is 5-10 ampere and 30-50 volts depending on the number of cells that are connected in series and their current and voltages.

The blocking diode ratings depend on the array current and the voltage because the main function of these diodes is to block the current coming from the battery during the night when modules do not produce any power.

The typical rating of the blocking diode ranges from a small current like 10s of an ampere to a large current like 100s of amperes for SPV arrays.

More: